Introduction

In a world where energy efficiency is of paramount importance, Insulated Gate Bipolar Transistors (IGBTs) play a pivotal role in controlling and regulating electrical energy. The transformative potential of IGBTs to manage energy systems will help to advance sustainability in the near future.

IGBTs Explained

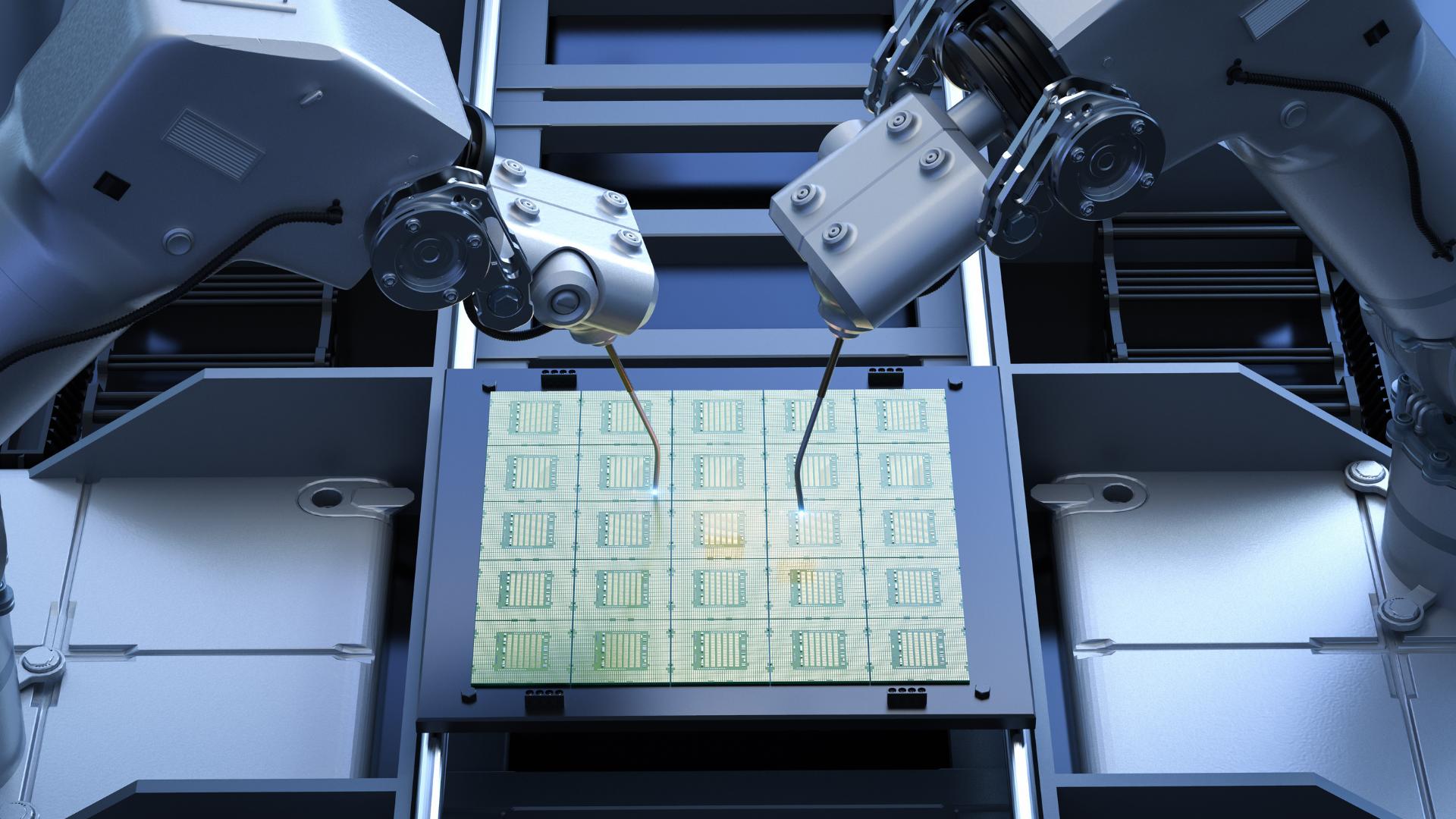

IGBTs are semiconductor switching devices that combine the voltage control capabilities of Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) and the current-carrying capabilities of Bipolar Junction Transistors (BJTs). This unique amalgamation empowers them to handle high voltages and currents while offering precise switching and control. IGBTs are primarily used in electric power conversion systems to control and manage the flow of electrical energy.

From Voltage Control to Energy Efficiency

In the decarbonisation landscape, the quest for energy efficiency has become a global imperative, and the significant improvement in IGBT performance has helped to improve the efficiency and control of electrical power. IGBTs are able to rapidly switch voltages with incredibly low switching losses, making them a desirable choice in renewable energy systems, such as solar inverters and wind turbines, along with other power conversion componentry.

Transforming Assets

The energy transition has created a pressing need to overhaul energy-intensive sectors, seeking fresh opportunities as we move away from fossil fuel assets. This window of opportunity is open for us to unlock new clean energy and productivity opportunities for these sectors.

Mining remains as one of the most energy-intensive industries in Australia. According to ARENA, it is estimated that the energy required to extract a tonne of product is estimated to be 50.5 kWh for coal. 10.7 kWh for minerals and 54.5 kWh for metals, mostly coming from the combustion of diesel, natural gas and grid energy. However, the challenge lies in the paradox: we cannot entirely phase out this industry due to its crucial role in extracting essential minerals and resources necessary for low-carbon technologies like wind turbines, solar panels and batteries. Nevertheless, there is scope for improving the sustainability of mining practices.

The solution to this paradox has become glaringly evident: the adoption of electrification and implementation of renewable energy. However this transition is not without its challenges, but has been greatly aided by the applications of IGBTs.

IGBTs have enabled the mining industry to create more energy-efficient equipment as they allow for precision in the control of power distribution in heavy machinery. In this way, there can be a reduction in waste energy and operating costs.

In 2023, an exciting opportunity emerged for Alta. We harnessed this technological advancement of IGBTs in developing a regenerative braking solution for mining trucks. This solution captures and stores all the braking energy which would otherwise be dissipated through the resistor grids, diverting it to an on-board battery. Subsequently, this stored energy can be utilised to supplement the diesel engine when the mining truck is in traction. The benefits are twofold: not only does it significantly reduce wasted energy but also reduces fuel consumption and emissions. The power of the IGBT was a key component of this solution, especially in the inverter and converter technology. Additionally, the precise control that IGBTs provide also enhances the safety of the system by reducing risks of accidents and equipment malfunctions.

Another complexity in electrification of heavy machinery is maintaining the original traction and power of the vehicle itself. However, IGBTs enable efficient power distribution, resulting in increased productivity while preserving consistent power and torque. This ensures that the haul truck’s original capabilities remain unaffected.

Renewable Energy Applications

IGBTs also have a role to play in renewable energy systems. They are an integral part of inverters which are responsible for converting DC generated by solar panels or wind turbines into AC, and ensuring compatibility with the local grid or loads. They are also used in batteries to manage the charging and discharging processes efficiently and optimising the use of the store energy.

There is continued research and innovation in the realm of IGBTs and it is important to understand and recognise the power of IGBTs in powering our progress towards a cleaner, more energy-efficient and sustainable world.

The Future of IGBTs

Currently the majority of IGBTs are made of silicon but have a fundamental disadvantage. The development of silicon carbide IGBTs is the next generation. The physical properties of silicon carbide are more favourable which allows it to be better applied in high temperature, high power, high voltage and high frequency applications. SiC-IGBTs also have even faster switching speeds which reduces switching losses and improves performance and efficiency which is a desirable trait as we progress towards further mining electrification.